Set Your Plant Up for Success

Producing asphalt is a tough business and it takes its toll on equipment, conveyors, belts, and scales.

With time the hard, rough-rock ultimately reduces accuracy – requiring recalibration over time.

Increase Your PWL & Pay Factor Bonus with Accurate Calibration

- Quality

If Mix quality issues arise, you can troubleshoot more easily if the scales are known to be calibrated.

- Process Control & Management

If Mix quality issues arise, you can troubleshoot more easily if the scales are known to be calibrated.

- Cost

If scales are calibrated before production begins, you prevent waste. The more accurate your calibration, the more accurate your mix, the greater your PWL and Pay Factor Bonus.

Some Tips to Help Start You Off for Success:

1.) Check all Hardware

Make sure all your hardware is in good working condition:

- Tachometers

- Load Cells

- Signal Conditioners (IND110 & SCT-20)

- PLC

- VFD Drives (be sure they are working and not faulty)

2.) Confirm Your Weighbridge is in Proper Alignment

Level Idlers and String-Line the Weighbridge:

- String a straight line across the bridge

- Make sure that no idler is more than 1/16" off the rest

- Extremely Important: Use the leveling bolts to adjust the scale idler height. Use a minimum of three strings to align all five weighbridge idlers, one at the tip of each wing roller and in the middle of the center roller. Shim the surrounding idlers if necessary.

- Ensure repeatable and accurate results from the scale. The scale idler rollers must be level with the two idlers before and after. The empty belt must rest uniformly on al idlers within the weighbridge.

- Be sure to tighten the lock nuts once the scale is at the proper height.

- Remember: a quality calibration will not be achieved without necessary adjustments. If adjustments are required, make them.

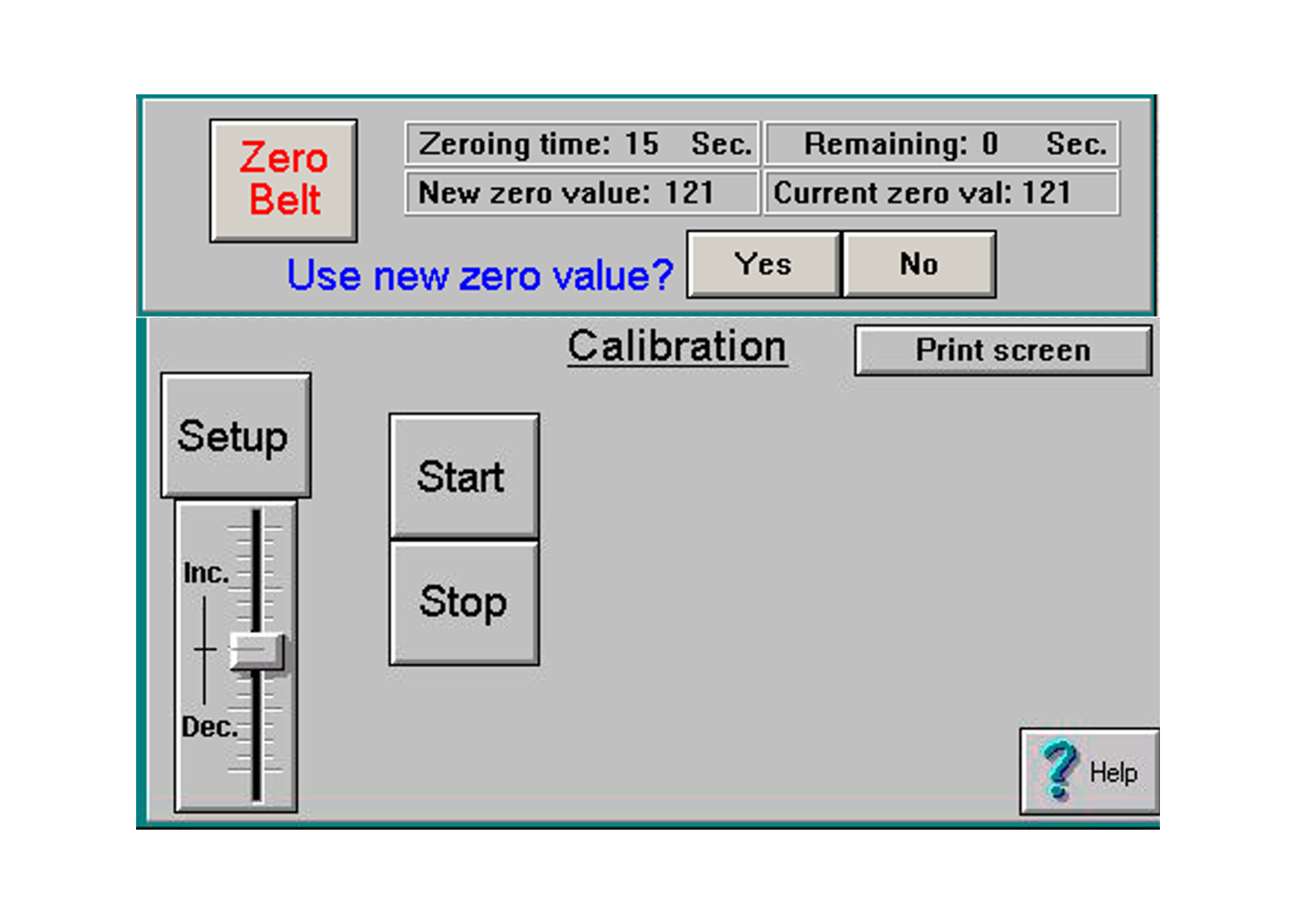

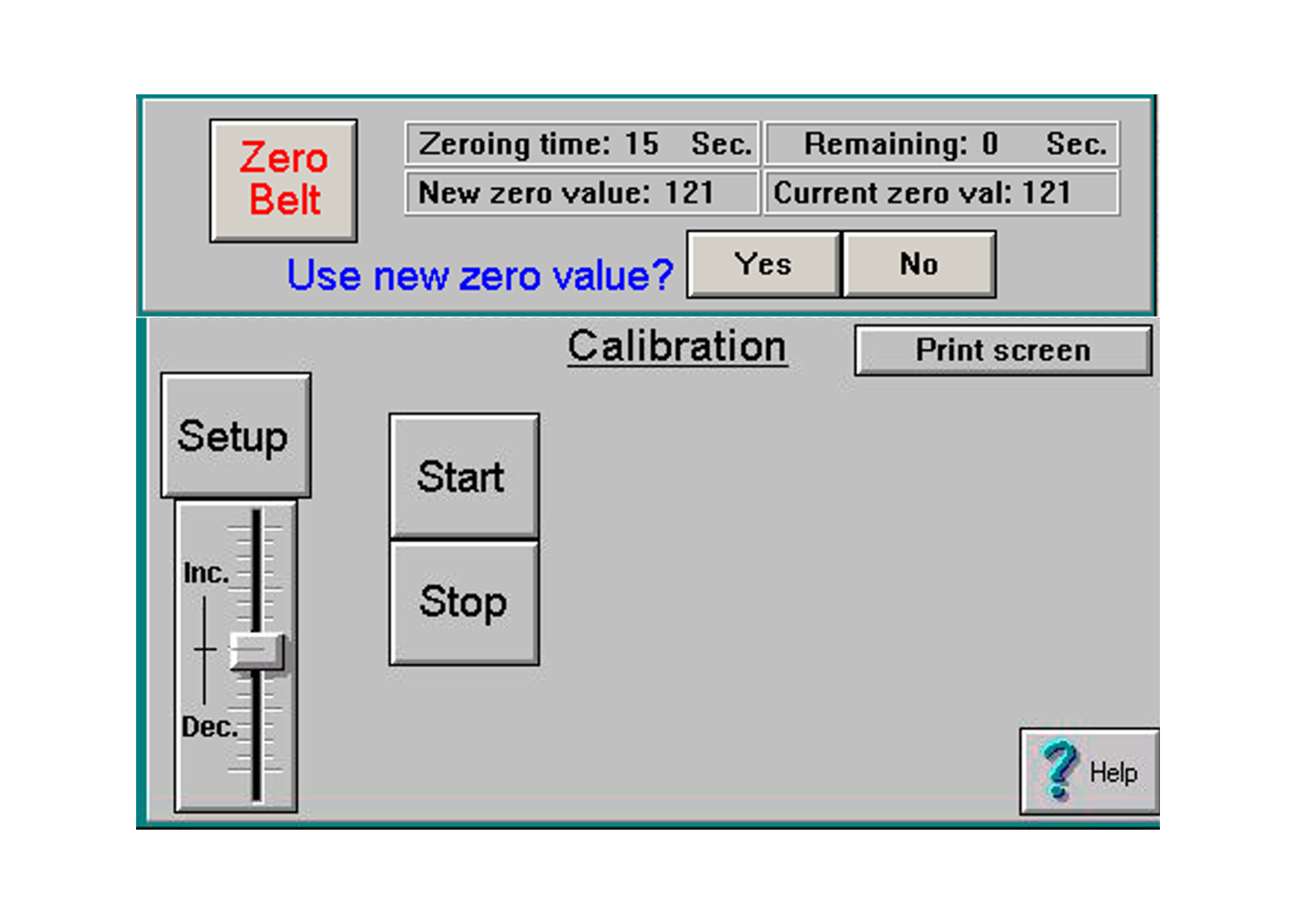

3.) Capture a Zero Weight

- Warm up the belt for at least a half-hour before you capture a Zero value.

- Knowing the time of a complete revolution is essential to calculate your zero weight.

- Remember: Your Zero weight is > 2 revolutions of the belt.

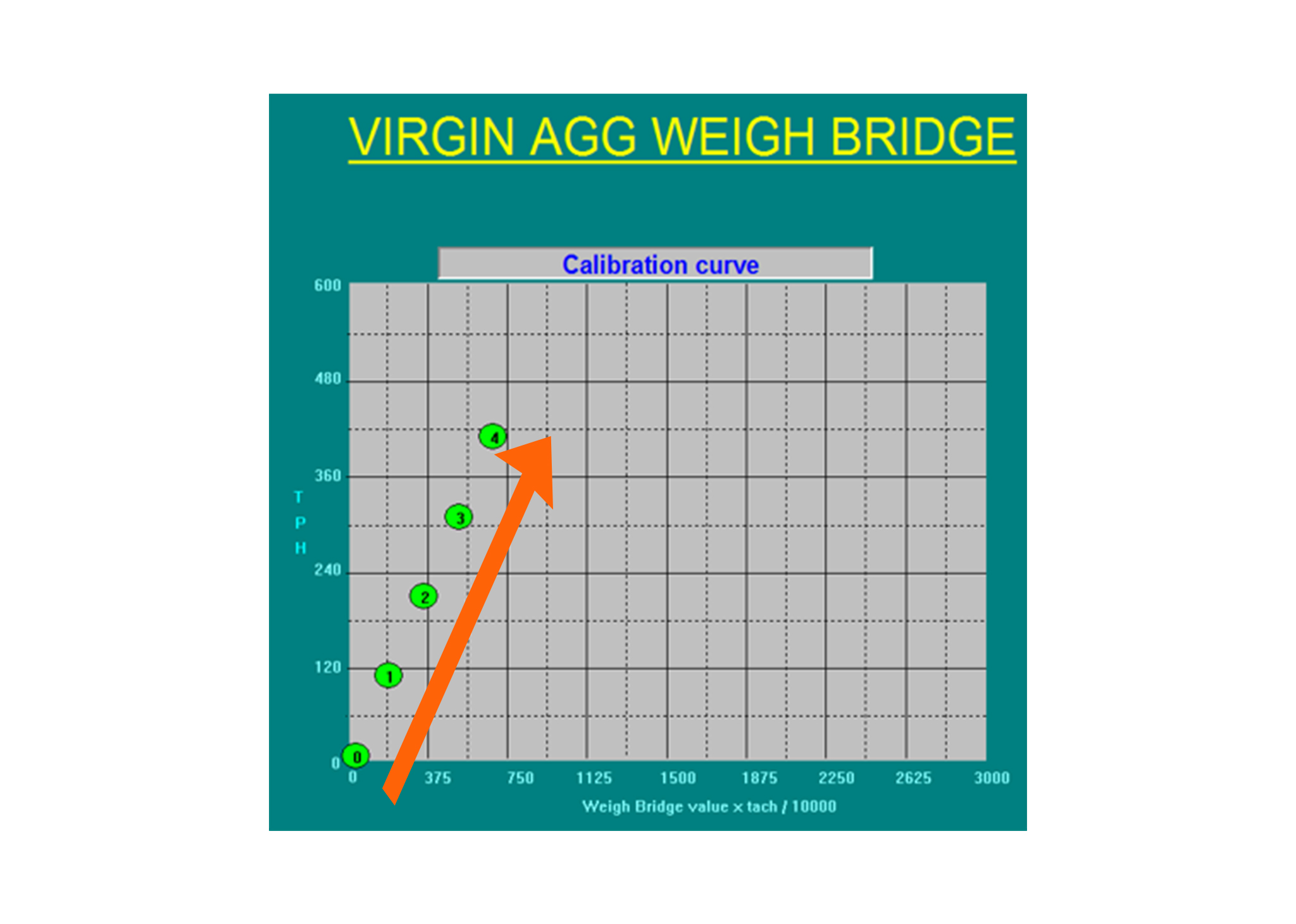

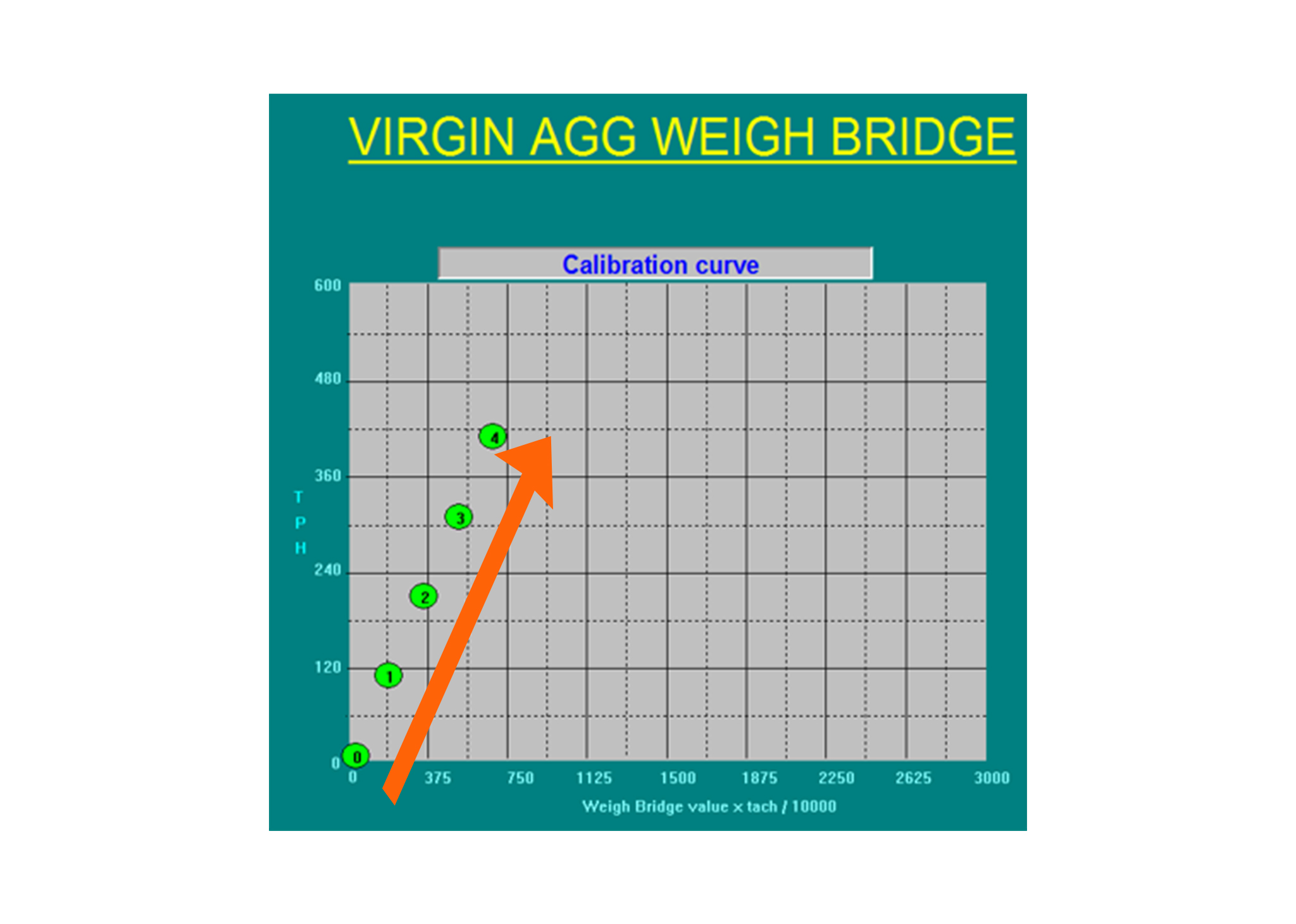

4.) Be Sure Your Calibration Points are Linear

Your Calibration points need to be linear and produce a straight line.

If not:

- Maybe your Bin went empty?

- Material Moisture may be different.

- There may be a Gate Opening Change - perhaps a large piece of solid material broke loose that was metering the bin opening.

Easy & Efficient

When Calibrating with a WEM system the process can be done in a matter of hours, not days compared to other systems.

WEM does all the math, you just have to enter the weights, and loadout a truck.

Calibrating your cold feeds is fast and easy. Simply set the feeder speeds, type in weights, and then run it. The system automatically cycles through each feeder and automatically calculates the delay times in a single pass.

Accurate & Flexible

For over 65 years WEM has helped customers with our calibration expertise. Over the years we have continuously improved our behind-the-scenes math so you can expect accurate results. No need for stop watches or math on the side, the WEM system does the math for you making calibration a very simple process.

You can calibrate the aggregate, AC, and RAP independently or all at once.

When recalibrating, you can use the old number, the new number, or an average of the two calibration factors.

Safe

You only need a spotter out in the yard for your first calibration point, after that simply sit back in the control room and let the WEM system do the work.

Ready to Learn More?

Feel free to reach out to us today! Our Service Technicians and Sales Representatives are happy to answer any questions regarding your Asphalt Plant calibration needs.