Getting Off to a Great Start!

Asphalt Cement (AC) is the most expensive material to create Asphalt.

Keeping your AC system calibrated and working in proper condition is very important, not only to manage operational costs, but also, to ensure you have consistent mix quality.

3 Important Tips for Accurate AC Calibration:

Help keep your AC system tuned with these Calibration tips!

1.) AC Temperature in Operating Range

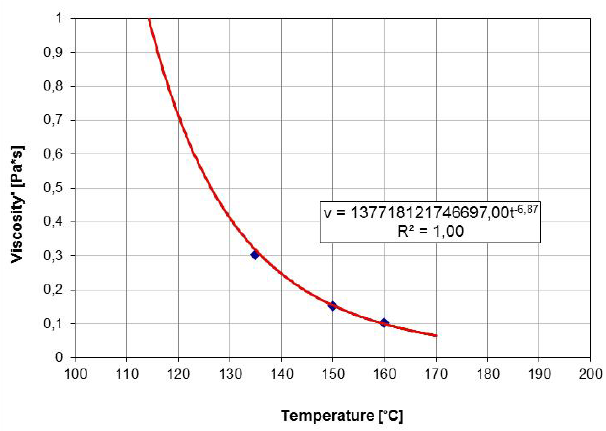

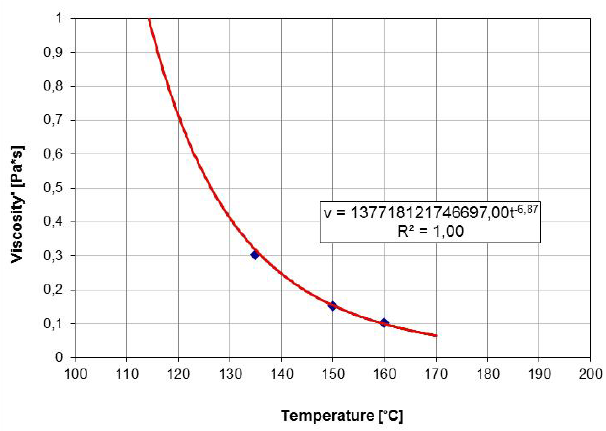

Prior to starting calibration, make sure your Asphalt Cement's temperature is in proper range. The flow characteristics change for AC at different temperatures, having the viscosity of your AC in proper range is very important. If your AC is not within operational temperature range during your calibration tests, you will not get accurate readings of the true volume of material you are adding to your mix.

2.) Check all AC Tank Valves

Check to make sure all AC Tank Valves are functioning properly. If your Valves are not functioning properly it will cause issues with start up, shut down, recirculating, and material changes.

It is important to pinpoint the problem and troubleshoot. Some common Tank Valve issues are:

- If the valve is slow actuating, the amount of material going through will be out of your desired range, until the valve is fully opened.

- If valves are sticking, it may be due to the fact your AC temperature is not warm enough.

- Check for leaking air lines to the air operated type valves.

3.) Assure there is Proper Flow Signal to the PLC

Confirm that your tachs or flow meters are in good operating condition, and are sending a good pulse signal to the PLC.

Each pulse sent to the PLC represents the weight of AC at the injection point. This is determined by the number of pulses received. An inaccurate pulse rate means you can end up with a poor calibration.

Remember, it is very important to not stop your calibration tests once you start. You should also save your screen once completed to document your calibration. Should you need to re-calibrate in the future, this document will serve as a good point of reference.

Also, if time is of the essence, while you are calibrating your AC you can also calibrate your weighbridges or virgin aggregate feeders at the same time. This cuts down on your calibration time so you can start making mix sooner.

Easy & Efficient

When Calibrating with a WEM system the process can be done in a matter of hours, not days compared to other systems.

WEM does all the math, you just have to enter the weights, and loadout a truck.

Calibrating your cold feeds is fast and easy. Simply set the feeder speeds, type in weights, and then run it. The system automatically cycles through each feeder and automatically calculates the delay times in a single pass.

Accurate & Flexible

For over 65 years WEM has helped customers with our calibration expertise. Over the years we have continuously improved our behind-the-scenes math so you can expect accurate results. No need for stop watches or math on the side, the WEM system does the math for you making calibration a very simple process.

You can calibrate the aggregate, AC, and RAP independently or all at once.

When recalibrating, you can use the old number, the new number, or an average of the two calibration factors.

Safe

You only need a spotter out in the yard for your first calibration point, after that simply sit back in the control room and let the WEM system do the work.

Ready to Learn More?

Feel free to reach out to us today! Our Service Technicians and Sales Representatives are happy to answer any questions regarding your AC or Asphalt Plant calibration needs.